CONTENT

- Presentation

- Presentation

- Services

- Applications

- Why choose us

PROVIDE COMPLETE SOLUTIONS TO THE PIPELINE INDUSTRIES

- FerroBend is an Indian entity specialized in the manufacturing and storage of piping products intended exclusively for the industrial piping sectors, combustible gas piping, electrical piping, and other disciplines of liquid hydrocarbon pipeline transport, refrigeration lines, heat transfer components, and gas transport and distribution systems. Its most well-known industrial application areas include chemical and food processing units, petrochemical plants, oil, gas, and steam transport pipelines, nuclear and thermal power plants, offshore engineering, mining, underwater piping, etc. FerroBend is young but relies on experienced partners, international counterparts, trusted collaborators, and a rigorous business ethics, enabling it to quickly establish itself in the sector.FerroBend values and understands the perception of its customers and suppliers and strives to create synergy between them, thus establishing long-term business relationships necessary for the growth and sustainability of its business.

-

Manufacturing

Comme tout artisan, nous sommes équipés de technologies modernes et des dernières normes industrielles pour répondre à toutes les exigences de fabrication dans le monde de la tuyauterie.Outsourcing

Leave the hard work to us. Our high-standard parallel team offers you the best products at affordable prices for your complete project. Leave the hard work to us. Our high-standard parallel team offers you the best products at affordable prices for your complete project.

MANUFACTURING RANGE

- PIPE FITTINGS

- Closed, welded end to end

- Closed, interlocking

- Closed, screwed/threaded

- Raccords fabriqués à partir de plaques

- Bar/Block Fittings

- Hygienic/sanitary pipe fittings

FLANGES

- To solder

- To fit together

- Socket welding

- Thread

- Lap joint

- Shady

- Orifice flange

- Longue bride à souder

FASTENERS

- Hexagonal bolts

- Studs

- Vis

- Nuts

- Washers

EXPANSION JOINTS

- Rubber expansion joints

- Metal expansion joints and Teflon expansion joints

- Nipo flange

- Weldom flange

- Reduction flange

- Expansion flange

- Nozzle Flange

- Glasses strap

- Flange and spacer

VALVES

- gate valve

- Globe valve

- Butterfly valve

- Membrane valve

- Ball valve

- Check valve

- Ball valve

- Knife tap

- Pinch valve

SHARE OWNERSHIP

- Seamless tubes

- Welded tubes

- Seamless tubes

- Welded tubes

- Hot rolled

- Cold rolled

- Laminates

- Forged

TUBE FITTINGS

- Instrumentation

- Hydraulic

- Pneumatic

PIPE FITTINGS

PIPE FITTINGS

An ISO 9001:2008 certified manufacturer of forged and butt-welded pipe fittings suitable for all types of services, FerroBend started production with duplex stainless steel butt-welded pipe fittings and has extensive expertise in the regular manufacture of low-temperature alloy steel, high-temperature carbon steel, and marine-grade copper-nickel. In addition to our standard range, we are experts in the manufacture of critical titanium, zirconium, and tantalum fittings. We can produce these pipe fittings in accordance with American, German, European, British, and ISO standards, as well as specifications and standards. industrielles supplémentaires.

Dimensional Range 3/8 to 24 Seamless, 3/8 to 60 Welded Categories Butt Weld Fittings Socket Weld Fittings Threaded Fittings Fabricated Fittings Block Type Butt Weld Fittings Branch Fittings Investment Casting Fittings Hygienic Pipe Fittings Materials Ductile Iron High Strength Carbon Steel Low Temperature Alloy Steel Stainless Steel Duplex Stainless Steel Super Duplex Steel Marine Grade Copper Nickel Corrosion Resistance Nickel Alloy Monel High Strength Inconel Crevice Resistance Hastelloy Aerospace Grade Titanium Tantalum and Zirconium Alloys Manufacturing Standards American ASME B16.9, B16.11, B16.28, B16.49 German DIN 2616-1, 2616-2, 2617, 2628, 2619, 2980, 2981, 2982, 2983, 2986, 2990, 2991, 2993, 2999-2, 28011 European standards EN 10253, 11851, 11852, 11853, 11864 British standards BS 1640 part 1, 1640 part 2, 1640 part 3, 1640 part 4, 1740, 3799, 4825 part 1, 4825 part 2, 4825 part 3, 4825 part 4 and ISO standards including ISO 3419 and ISO 5251.

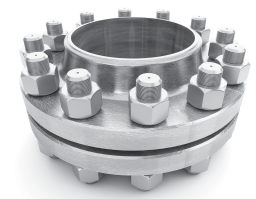

PIPE FLANGES

Precision forged and machined pipeline flanges for oil and gas platforms, petrochemicals, nuclear and thermal power extraction, marine and offshore engineering, metallurgical and mining facilities, etc. FerroBend manufactures and supplies CNC machined flanges for extreme precision, required for critical work, with value-added services like coating and third-party inspection. These flanges can be forged or formed to the desired size and tolerances, in accordance with various manufacturing standards, including American, German, European, British, Japanese, Russian, and ISO.

Size Range 1/2 NPS to 96 NPS Pressure Ratings 75 LBS up to 2500 LBS, PN1.6 to PN400 Standard Pipe Flanges Weld Neck Flange, Socket Flange Socket Weld Flange, Threaded Flange Lap Flange, Blind Flanges Specialty Flanges and Accessories Long Weld Neck Flange, Orifice Flange Expansion Flange, Reducing Flange Weldo Flange, Nipo Flange, Nozzle Flange Spectacle, Blind & Gap Plug Material Offered Ductile Iron, High Strength Carbon Steel, Low Temperature Alloy Steel Stainless Steel, Duplex Stainless Steel, Super Duplex Steel Marine Grade Copper Nickel, Corrosion Resistant Nickel Monel Alloy, High Strength Inconel, Crevice Resistant Hastelloy Aerospace Grade Titanium, Tantalum & Zirconium Alloys Manufacturing Standards American ASME B16.5, B16.36, B16.47 Series A and B, AWWA C207, API 6A and API 605 German DIN 2527, 2573, 2576, 2502, 2503, 2630, 2631, 2632, 2633, 2634, 2635, 2636, 2638, 2628, 2629, 2627, 2641, 2642, 2565, 2566, 2567, 2568, 2569, 28115 European EN 1092-1 BS10, 1560 and 4504 Japanese MSS-SP-44 Russian JIS B2220 GOST 12815, 12820, 12821, 12836 South African SABS 1123

FASTENERS

FerroBend offers a comprehensive range of fasteners in various shapes, sizes, materials, and dimensions. From high-strength fasteners to ultra-critical zirconium bolts, FerroBend provides a comprehensive range of fasteners that meet the required specifications and industry standards. Additionally, these fasteners are very useful for connecting flanges and flanged fittings in piping systems. Hex bolts, studs, cap screws, socket head cap screws, hex nuts, heavy hex nuts, cap nuts, flat washers, and spring washers are some of the fasteners commonly used in piping systems.

Dimensional range

M1 to M110 (metric) and No. 0 to 4 (imperial). Common fasteners: Hex bolts, heavy hex bolts, machine screws, studs, socket head cap screws, grub screws, flange bolts, hex nuts, heavy hex nuts, thin lock nuts, cap nuts, hex coupling nuts, flat washers, spring washers, lock washers, dowel pins

Material Category: High strength carbon steel, low temperature alloy steel, stainless steel, duplex stainless steel, super duplex steel, marine grade nickel copper, corrosion resistance, nickel-monel alloy, high strength Inconel, crack resistance, Hastelloy, aerospace grade titanium, nitronic and nimonic alloys, silicon, aluminum and phosphor bronze alloys, tantalum and zirconium alloys

Material specifications ASTM A193, A307, A320, A325, A449, A490, A540, A574, F468, F593, F835, F837, F2281 BS EN ISO 3506-1

Dimensional standards DIN 912, DIN 913, DIN 916, DIN 931, DIN 933, DIN 934, DIN 939, DIN 940, DIN 976, DIN 439, DIN 125, DIN 127, DIN 2510 ISO 4014, ISO 4017, ISO 4032, ISO 4034, ISO 4762, ASME B18.2.1, ASME B18.3, ASME B18.2.4.1M, ASME B18.2.2, etc. Most common dimensional standards for fasteners

Coatings: Plain finish, zinc plated, cadmium plated, hot-dip galvanized, phosphated, PTFE coated, black zinc, aluminum flakes, electrolytic copper, nickel plated and chrome plated. Thread types: Unified National Thread UNC, Unified National Coarse Thread, UNF, Unified National Fine Thread, UNEF, Unified National Extra Fine Thread, UNS, Unified National Special Thread, UNR, Unified National Round Thread (Round Bottom), ISO, International Organization for Standardization (Metric), BSW, British Standard Whitworth, BSF, British Standard Fine.

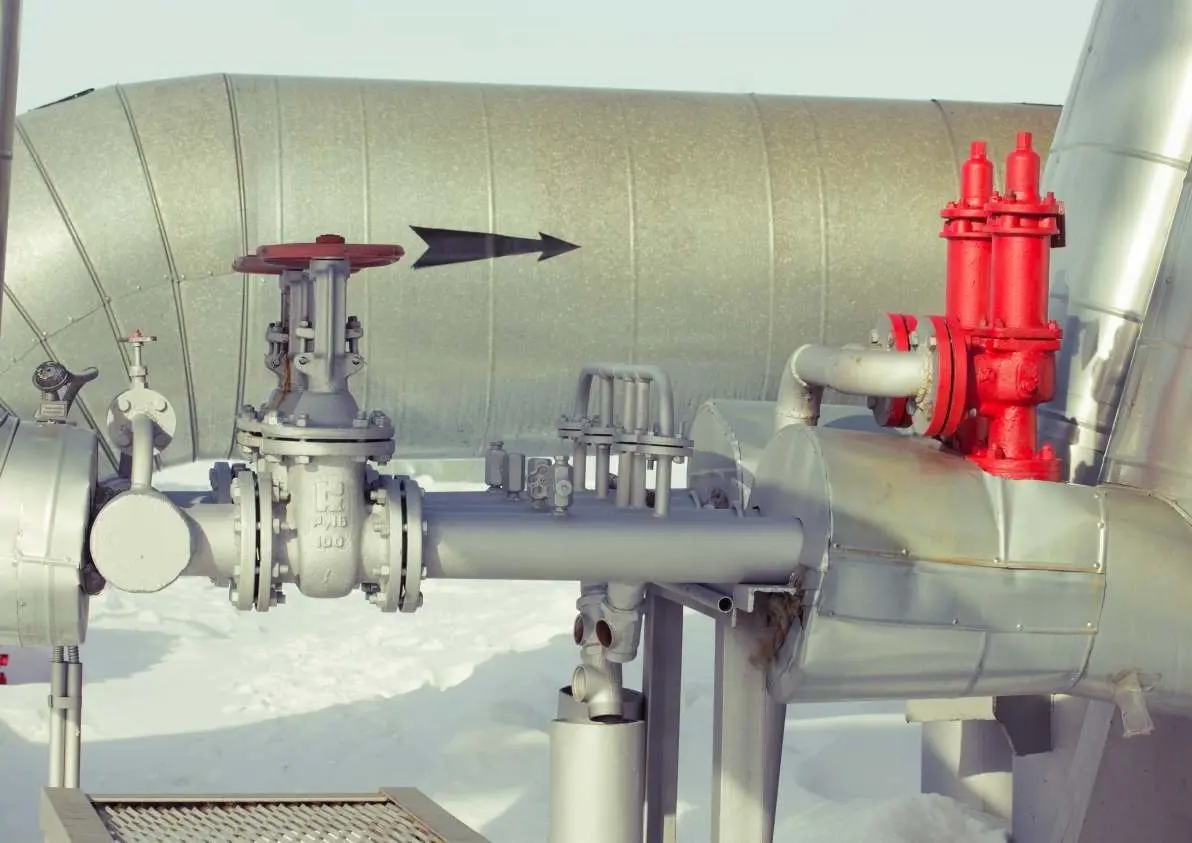

INDUSTRIAL VALVES

Valves are essential to the operation of any piping system. FerroBend works with a network of long-established partners and manufacturing companies, allowing us to maintain a stable inventory of industrial valves, including gate, globe, butterfly, pinch, diaphragm, and more. FerroBend also manufactures small-bore ball valves, needle valves, check valves, and manifolds in-house. These valves are either cast or forged. Our team works closely with these companies to ensure consistent quality and precision. These valves are manufactured to the latest industry standards and specifications.

Dimensional range

3/8 à 96

Types of Industrial Valves: Gate Valve, Globe Valve, Butterfly Valve, Diaphragm Valve, Plug Valve, Check Valve, Ball Valve, Knife Gate Valve, Sleeve Valve

Materials offered: Ductile iron, High strength carbon steel, Low temperature alloy steel, Stainless steel, Duplex stainless steel, Super duplex steel, Marine grade copper, Nickel, Corrosion resistance, Nickel-monel alloy, High strength Inconel, Crack resistance, Hastelloy, Aerospace grade titanium, Tantalum and zirconium alloys

Dimensional standards: API 595, API 599, API 600, API 602, API 6D, API 609, BS EN 593, BS 5153, DIN 3202, DIN 3352, DIN 11851 and ISO 5752.

EXPANSION JOINTS

Expansion joints are used in piping systems to accommodate thermal expansion when the use of expansion loops is undesirable or impractical. FerroBend excels in the manufacture and supply of metal, Teflon, and rubber expansion joints. Expansion joints, also known as expansion bellows, are designed for linear, lateral, and axial stresses. Depending on the pipe type, expansion joints can be offered with butt-welded, threaded, or flanged connections. Flanges comply with ASME B16.5, B16.47, API 6A, API 605, MSS-SP-44, EN 1092-1, and various DIN dimensional standards.

Dimensional range from 1/2 to 60 NPS

Nominal pressures from 34 to 1137 kg and PN1.6 to PN400

Standard types: tapered joints, offset joints, sleeve joints, full arches, multiple arches, rectangular, no arch and wide arch.

Construction: Metal >> Free-type, rod-guided, gimbal, articulated, universal, reinforced and pressure-balanced. Rubber >> Single sphere, double sphere, coil. Teflon >> Teflon-coated metal and rubber expansion joint

End Fittings: Butt Welded, Threaded and Flanged

Materials offered: Metallic >> Ductile iron, carbon steel, alloy steel, stainless steel, duplex and super duplex stainless steel, copper-nickel, titanium, tantalum, zirconium, copper and bronze. Non-metallic >> Teflon and rubber

Design Standards: These expansion joints are customized to customer requirements, taking into account pressure/temperature ratings, design length, and desired end connections. Flanges conform to ASME B16.5, B16.47, MSS-SP-44, JIS B2220, BS10, 1560, EN 1092-1, and DIN standards.

Value-added services

- Custom cutting

- Custom manufacturing

- Forgings

- Thermal treatment

- Coating and surface finishing

- Perforation work

- third party inspection

Testing and Inspection Center

- Value of the chemical composition of steel: casting, product

- Dimensional controls

- Mechanical properties: tensile strength, hardness, impact bending test

- Technological tests: flattening, flaring, flanging, folding, ring test

- Waterproofing: hydropressure test, non-destructive methods

- Non-destructive testing (eddy currents, stray flux, ultrasound): longitudinal defects, transverse defects, duality

- Additional tests (metallography, corrosion resistance, etc.)

Certification

- Acceptance test certificate 3.1.

- Acceptance test certificate 3.1.B

- Acceptance test certificate 3.1.C

- Acceptance test certificate 3.2

Action program

FerroBend carries a comprehensive inventory of standard carbon steel, chrome-molybdenum alloy steel, stainless steel, and duplex stainless steel tubing and pipe. Available sizes range from 1/2 to 24 inches (1.25 to 61 cm) for stainless steel and nickel alloys, and from 1/2 to 48 inches (1.25 to 122 cm) for carbon and alloy steel. Other products include boiler-grade sheet, alloy steels, stainless steel, copper-nickel alloys, high nickel, titanium alloys, and more.

Logistic

Orders are carefully protected from damage and shipped with the utmost care. We offer comprehensive shipping methods, combined with our expertise in international freight forwarding and logistics. Our logistics team is in constant contact with the cargo and keeps you informed until it reaches its destination. We offer a hassle-free shipping experience with the following partners.

Areas of application

- OIL AND GAS REFINING

- NUCLEAR AND THERMAL ENERGY PRODUCTION

- EXTRACTION OF METALS AND MINERALS

- AEROSPACE AND DEFENSE FACILITIES

- SEAWATER DESALINATION

- CHEMICAL AND PETROCHEMICAL INDUSTRIES

- FOOD AND BEVERAGE PROCESSING PLANTS

- AIR SEPARATION AND CRYOGENICS SYSTEMS

- UNDERWATER PIPELINES

- MANUFACTURE OF HEAT EXCHANGERS, CONDENSERS, ETC.

- SHIPBUILDING AND MARINE ENGINEERING

- OIL, GAS AND STEAM TRANSPORT PIPESR

Works1:

1754, R. K. Industrial Park, Off NHS Highway, Ra|kot, Gujarat, INDIA

Tel.: +91 80 8060 8753

Works II :

C-120, Marudhar Industrial Estate,

Thane, Maharashtra, INDIA.

Tel.: +91 22 4004 4000

Email : sales@ferrobend.com

Fully dedicated to the piping sector

FerroBend dedicates its operations and efforts to the development of the piping industry and aims to operate for process piping, power piping, fuel and gas piping, hydrocarbon and fluid transportation systems, heat exchangers and condenser piping systems.

Equipped with technical know-how

FerroBend aspires to become the largest piping solutions provider in India. To achieve this, we understand the need to evolve, diversify, and adapt to new and promising technologies to deliver the best in the piping industry..

Offers products with global standards

With the ambition to serve the global platform, FerroBend recognizes the need to improve its production with modern technologies and the latest advancements in the industry. FerroBend also offers products compliant with American, German, European, Japanese, and Indian standards.

Global resources with local support

With three decades of experience, FerroBend has inherited all of its parent company's global resources to meet all your piping needs. Whether it's metals, alloys, or rare-earth products, FerroBend has you covered.

Warehouse I :

226/1-2, Rai Village, Ultan Road, Thane, Maharashtra, INDIA.

Warehouse II :

111, 5 5 Marg.

Two Tank, Mumbor, Maharashtra, INDIA,

FERROBEND 1016, Prasad Chambers, Tata Road No. 1 & 2, Opera House, Mumbai 400004, Maharashtra, India. Tel. : +91 22 6666 5432 info@forrend.com www.forrend.com